Research and development of using earthen materials for construction is gaining pace. Soil science is rapidly becoming the catalyst for a much needed solution to reduce greenhouse gases within the construction sector and raw material selection appears to be the place of choice to start.

Mineral Extraction

Masonry building products such as concrete blocks and fired bricks still account for a large percentage of new build principal fabric. However, creating these products requires vast amounts of energy and resources. Targeted mineral extraction for specific end use is not only tearing up the landscape but also demands extensive fuel requirements. Reassuringly, this is flagged and the onset of by-product ‘waste’ [from other industries] being used instead, is definitely a step in the right direction.

Processing

Stockpiles of unprocessed raw materials require transportation from source to plant. OK, in some instances this could be conveyed only a small distance across site, but it still requires energy. But not all extraction sites have processing facilities and therefore raw materials require delivery to processing plants…more energy.

Processing raw material principals are simple….crush to desired grit size.

Processing raw materials in practice…..demand high levels of energy input.

Cement

Cement plays a key role in the construction industry, we know that….and quite honestly I find this product absolutely amazing! It’s versatile, easy-to-use and readily available. What would we do without it? Everywhere we go we’ll encounter this building medium and it still retains top-spot as the go-to material. So…let’s not try and eradicate its demand and use, why not embrace its in-situ attributes and at the same time endeavour to lower reliance? A reduction in user/specifier demand would surely tick a few boxes, reduce carbon emissions and encourage exploration into alternative materials.

Energy Requirements

Alternative Raw Materials

Raw materials such as clayey soils are prominent around the world. Building with earth isn’t new and building with earth blocks isn’t either. However, in-depth knowledge and modern technologies are helping to springboard this somewhat humble material back into justified existence. Here at Earth Blocks Ltd we have been researching, analysing and developing techniques for earth block manufacture and earth block efficiency for many years and while this journey continues, presently we are in a good place.

Here’s why – we have remained faithful to the two most important facets of sustainability – low embodied carbon and (100% natural material) product efficiency.

Sourcing Sustainable Raw Materials

Globally, most construction projects will require excavation of sub-ground and, more often than not, these substrates contain clay. The presence of clay [in sub-soils] used for earth in construction is crucial….this basic and natural element plays a key role in all earth building scenarios. Clay is the binder and when hardened provides the strength needed to manage load.

So, what if we were to use these extracted clayey soils from development sites to produce a building block?

A building block that is made of 100% natural material.

A building block that is strong.

A building block that is naturally thermally efficient.

In addition, what if we can manufacture these blocks on site?

Energy Requirements (Earth blocks)

Earth Block Making Machines

At the top of this post we talked about new technologies that can drive earth science research and development forward. Earth Blocks Ltd have designed and created the vehicles to take earth-in-construction to new heights of recognition and acceptance.

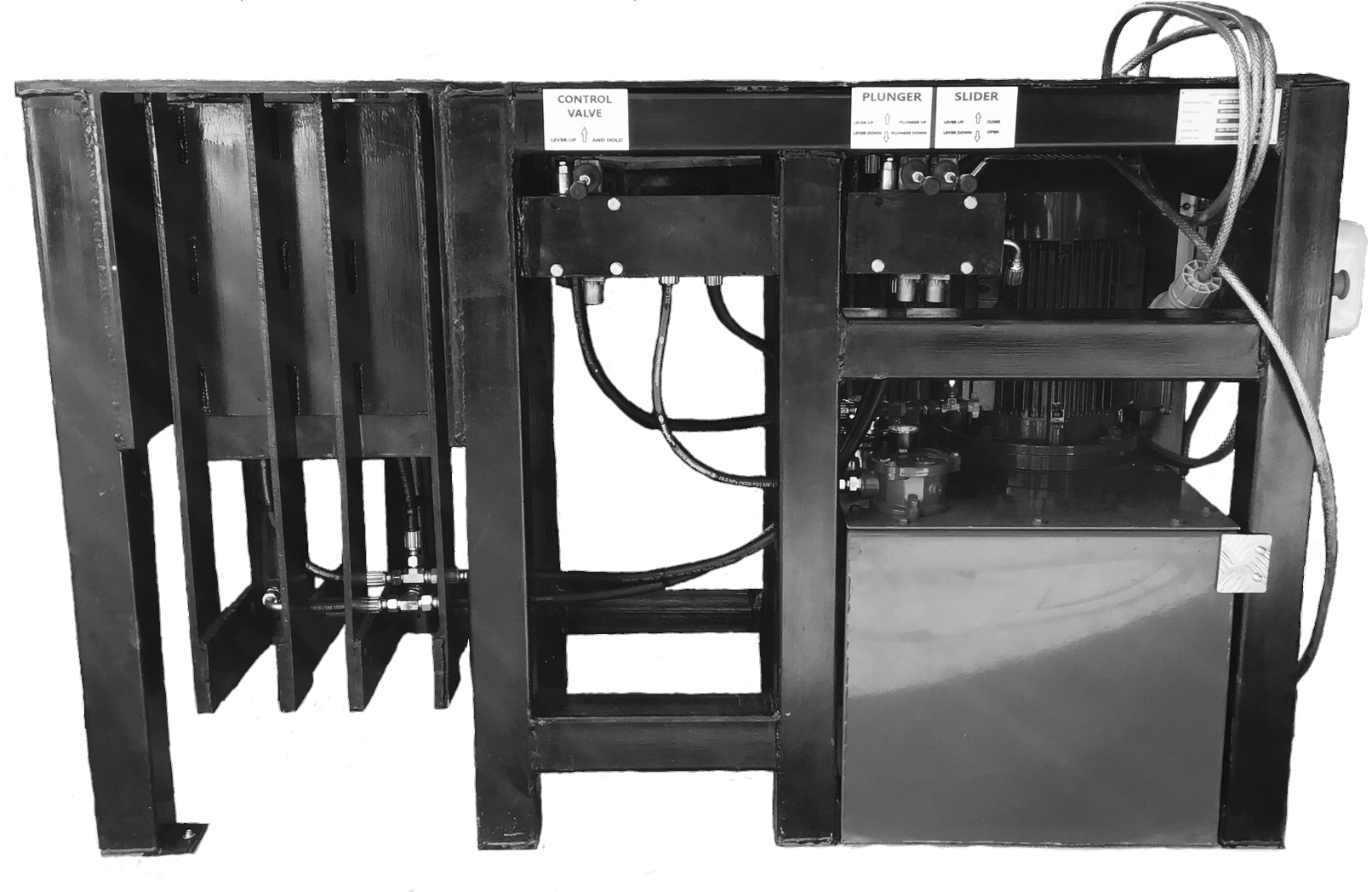

Pictured is our 300 Series of earth block making machine. Designed to make earth blocks of any chosen thickness (up to 150mm), this earth block machine can produce up to 100 blocks per hour. Compact and relatively lightweight this model of earth block making machine sits comfortably in areas that may have restricted space. Designed for, but not restricted to, earth sciences and research.

Standard earth block making machine with power pack

Our Standard earth block making machine (pictured) has been designed to receive hydraulic power from a wide range of sources. Portable, hydraulic power-packs are widely available from most UK tool hire centres and these power-packs are easily connected to the earth block machine with [supplied] push-fit couplings. Alternatively, our Standard earth block making machines can be connected to the hydraulic take-offs of tractors, diggers, forklifts etc and will happily make earth blocks all day long. Our Standard model of earth block machine requires no electrical power and is therefore easily transported to/operated at the heart of the raw material stockpile.